Heat Exchanger Interface (G)

Thermal interface between a gas and its surroundings

Libraries:

Simscape /

Fluids /

Heat Exchangers /

Fundamental Components

Description

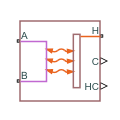

The Heat Exchanger Interface (G) block models thermal transfer by a gaseous flow within a heat exchanger. Use a second heat exchanger block to model the fluid pair. The interfaces can be in different fluid domains, such as one in liquid and one in gas. Use an E-NTU Heat Transfer block to couple the interfaces and capture the heat exchange between the fluids.

Mass Balance

The fixed-volume construction of the block allows you to capture variations in fluid mass flow rates due to compressibility. The overall mass accumulation rate is equal to the sum of the mass flow rates through the ports:

where is the mass accumulation rate and is the mass flow rate. The subscripts denote ports A and B. The mass flow rate is positive when it is directed into the gas channel.

When you select Enable dynamic compressibility, the mass accumulation rate accounts for variations in density:

where:

ρ is density.

p is pressure.

u is specific internal energy.

V is volume.

When you clear the Enable dynamic compressibility checkbox, the mass accumulation rate, , is zero.

Momentum Balance

Balancing momentum between the inlet and outlet ports of the heat exchanger dictates the flow direction and speed within the exchanger. Changes in momentum are due primarily due to friction losses from pipe turns, which translate to changes in pressure. Local resistances, such as bends, elbows, and tees can result in flow separation that leads to minor additional pressure losses. For steady flows, the mass flow rate remains constant.

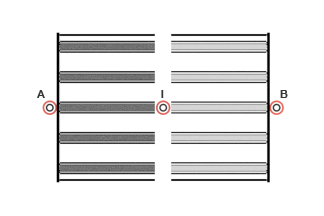

A momentum balance is applied to each segment of the gas (pipe) volume. This

figure shows a tube bank divided into two volumes and three nodes. The nodes

correspond to ports A , B, and the fluid

volume, I. Fluid states, such as pressure and temperature, and

fluid properties, such as density and viscosity, are defined at these nodes.

Note that flow inertia is negligible and the flow is considered to be quasi-steady state. The translation of transients to mass flow rates can be offset: due to coupling between density, pressure, and temperature, propagation of changes throughout the system is not instantaneous. Other sources and sinks of momentum, such as differences in head between ports or radial deformations of the channel wall, are not considered. The momentum balance for the half volume at port A is:

where p is the pressure at the node indicated in the subscript. Δpf,A is the total pressure loss between the port node and the internal node due to friction. The total pressure loss includes both major and minor losses. For the half volume at port B, the momentum balance is:

Friction

Pressure changes due to friction vary with the square of the mass flow rate for turbulent flows and with the magnitude of the mass flow rate for laminar flows. This pressure change is characterized by three dimensionless parameters: the Darcy friction factor, the pressure loss coefficient, and the Euler number. These numbers are calculated from empirical correlations or are estimated from lookup tables, depending on the Pressure loss model parameter.

Classification of "laminar" or "turbulent" flow is based on the Reynolds number. When the Reynolds number is above the Turbulent flow lower Reynolds number limit parameter, the flow is fully turbulent. Below the Laminar flow upper Reynolds number limit parameter, the flow is fully laminar. Reynolds numbers in between these values indicate transitional flow. Transitional flows show characteristics of both laminar and turbulent flows. In the Simscape™ Fluids™ language, numerical blending is applied between these bounding values.

Correlation for flow inside tubesFor tubes, the Darcy friction factor, fD, is used. In the half volume at port A, the momentum balance is:

where L is the tube length and LAdd is the added tube length that would reproduce the minor viscous losses if used in place of elbows, tees, unions, or other local resistances. A is the tube cross-sectional area; in the event of a non-uniform cross-sectional area, Amin should be used. DH is the tube hydraulic diameter, or the diameter of a circle equal in area to the tube cross section:

If the tube has a circular cross section, the hydraulic diameter and the tube diameter are the same.

For the half volume at port B, the momentum balance is:

For turbulent flows, the Darcy friction factor is calculated with the Haaland correlation. The Reynolds number is established at the bounding port:

where εR is wall roughness, taken as a characteristic height. This parameter is specified in the Internal surface absolute roughness parameter.

For laminar flows, the friction factor depends on the tube shape and is calculated with the tube shape factor:

where λ is the shape factor. The Reynolds number is calculated at the bounding port as:

Substituting Re into the pressure loss equation at port A, the momentum balance is reformulated as:

Likewise, for the half volume at port B, the momentum balance is:

For channels other than tubes, use the pressure loss coefficient, ξ. For turbulent flows in the half volume at port A, the momentum balance is:

For turbulent flows in the half volume at port B, the momentum balance is:

For laminar flows in the half volume at port A, the momentum balance is:

where ReL is the Laminar flow upper Reynolds number limit block parameter. For laminar flows in the half volume at port B, the momentum balance is:

Tabulated data - Darcy friction factor vs. Reynolds

numberYou can use tabulated data to determine the Darcy friction factor based on the Reynolds number for tube flows. For the half volume at port A, the momentum balance is:

For the half volume at port B, the momentum balance is:

For the turbulent regime, the friction factor is determined from a tabulated function of the Reynolds number:

The breakpoints of the tabulated function derive from the vector block parameters. The Reynolds number vector for Darcy friction factor parameter specifies the independent variable and the Darcy friction factor vector parameter specifies the dependent variable. Linear interpolation is applied between breakpoints. Outside of the tabulated data range, the nearest breakpoint determines the friction factor.

In the laminar regime, the friction factor is calculated from the shape factor, λ:

Tabulated data - Euler number vs. Reynolds

numberYou can use tabulated data to determine the Euler number based on the Reynolds number. This calculation is dependent on flow regime, and the Euler number is formulated as a tabulated function of the Reynolds number:

The breakpoints in Tabulated data - Euler number vs. Reynolds

number are specified by Reynolds number and Euler number

vectors. The Reynolds number vector for Euler number

parameter specifies the independent variables, the Reynolds numbers, and the

Euler number vector parameter specifies the dependent

variable, the Euler number, at each Reynolds number. Linear interpolation is

used to determine values between breakpoints. Outside of the tabulated data

range, the value at the nearest breakpoint is used.

For turbulent flows, the momentum balance for the half volume at port A is:

where Eu is the Euler number at port A. For turbulent flows, the momentum balance for the half volume at port B is:

For laminar flow in the half volume at port A, the momentum balance is:

where ReL is the Laminar flow upper Reynolds number limit parameter and EuL is the Euler number evaluated from tabulated data at that Reynolds number. For laminar flow in the half volume at port B, the momentum balance is:

Energy Balance

Energy can enter and exit the thermal interface in two ways: with fluid flow through ports A and B and with heat flow through port H. When you select Enable dynamic compressibility, the energy balance is

where:

E is the total energy in the internal fluid volume of the thermal interface.

ϕ* are the energy flow rates in through the gas ports.

Q is the heat flow rate in through the thermal port.

If you clear the Enable dynamic compressibility checkbox, the energy balance is

where the total internal energy is

The block calculates the constant ρ0 from the Nominal liquid temperature and Nominal liquid pressure parameters.

Heat Transfer Rate

Heat transfer between the two heat exchanger fluids occurs in multiple ways: through convection at the fluid interfaces, conduction through layers of built-up fouling, and conduction through the thickness of the wall.

Heat transfer extends beyond the gas channel and therefore requires other blocks to model the entire heat exchanger system. A second heat exchanger interface block models the second flow channel while an E-NTU Heat Transfer block models the heat flow across the wall. Heat transfer parameters that are specific to the gas channel, but required by the E-NTU Heat Transfer block, are available through the physical signal ports:

Port C outputs the heat capacity rate, which is a measure of the gas' ability to absorb heat and is required for calculating the number of heat transfer units (NTU). The heat capacity rate is calculated as:

where CR is the heat capacity rate and cp is the specific heat.

Port HC outputs the heat transfer coefficient, U.

If the heat transfer coefficient is treated as a constant, its value is uniform across the flow channel. If the heat transfer coefficient is variable, it is calculated at each port from the expression:

where Nu is Nusselt number, k is thermal conductivity, and DH,Q is a hydraulic diameter for heat transfer. The hydraulic diameterDH,Q is calculated as:

where SQ is the Heat transfer surface area parameter and LQ is the Length of flow path for heat transfer parameter.

The lower bound of the mean heat transfer coefficient is the Minimum gas-wall heat transfer coefficient parameter.

Nusselt Number

The Nusselt number is derived from empirical correlations with the Reynolds and Prandtl numbers. Use the Heat transfer parametrization parameter to select the most appropriate formulation for your simulation.

The simplest parameterization, Constant heat transfer

coefficient, obtains the heat transfer coefficient directly from

the value of the Gas-wall heat transfer coefficient parameter.

Correlation for flow inside tubes uses analytical

expressions with constant or calculated parameters to capture Nusselt number

dependence on the flow regime for tube flows.

The remaining parameterizations are tabulated functions of the Reynolds number. These are useful for varying Nusselt numbers, or heat transfer coefficients, across flow regimes. The functions are generated from experimental data relating the Reynolds number to the Colburn factor or the Reynolds and Prandtl numbers to the Nusselt number.

Constant heat transfer coefficientUsing Constant heat transfer coefficient, specified

in the Gas-wall heat transfer coefficient parameter, sets

the heat transfer coefficient as a constant, and does not use the Nusselt number

in calculations. Use this parameterization as a simple approximation for gas

flows confined to the laminar regime.

Correlation for tubesThe Nusselt number depends on flow regime when using Correlation

for tubes. For turbulent flows, its value changes in

proportion to the Reynolds number and is calculated from the Gnielinski correlation:

where Re is the Reynolds number, Nu is the Nusselt number, and Pr is the Prandtl number. The friction factor, f, is the same as the factor used in tube pressure loss calculations. For laminar flows, the Nusselt number is a constant. Its value is obtained from the Nusselt number for laminar flow heat transfer parameter, NuL:

Tabulated data - Colburn factor vs. Reynolds

numberYou can use tabulated data to determine the Colburn factor based on the Reynolds number. The Colburn equation is used to determine the Nusselt number, which varies in proportion to the Reynolds number. The Colburn j-factor is a measure of proportionality between the Reynolds, Prandtl, and Nusselt numbers:

ReQ is the Reynolds number based on the hydraulic diameter for heat transfer, DH, Q, and from the minimum free-flow area of the channel, AMin:

Tabulated data - Nusselt number vs. Reynolds number and

Prandtl numberYou can use a tabulated function to determine the Nusselt number from the Prandtl and Reynolds numbers. Linear interpolation is used to determine values between breakpoints. The Nusselt number is a function of both Re and Pr, and therefore the Reynolds number vector for Nusselt number, Prandtl number vector for Nusselt number, and Nusselt number table, Nu(Re,Pr) parameters define the table breakpoints:

The tabulated Reynolds number must be calculated using the hydraulic diameter for heat transfer, DH,Q.