Pressure-Reducing Valve (IL)

Pressure-reducing valve in an isothermal liquid network

Libraries:

Simscape /

Fluids /

Isothermal Liquid /

Valves & Orifices /

Pressure Control Valves

Description

The Pressure-Reducing Valve (IL) block represents a pressure-reducing valve in an isothermal liquid network. The valve remains open when the pressure at port B is less than a specified pressure. When the pressure at port B meets or surpasses this pressure, the valve closes. The block operates based on the differential between the set pressure and the pressure at port B. The block contains a check valve portion that functions identically to the Check Valve (IL) block during flow reversals. For pressure control based on another location in the fluid network, see the Pressure Compensator Valve (IL) block.

Set Pressure Control

The block regulates pressure between the set pressure and maximum pressure. When you set Set pressure control to:

Controlled— You can connect a pressure signal to port Ps. The block regulates pressure when the pressure at port B is greater than the reference set pressure, Pset, and below Pmax. The pressure at port B acts as the control pressure, Pcontrol, for this valve.Pmax is the sum of Pset and the pressure regulation range.

Constant— The Set pressure (gauge) parameter defines a constant set pressure.

How the block determines the pressure regulation range depends on the Opening parameterization parameter:

Linear - Area vs. pressure— The Pressure regulation range parameter defines the pressure regulation range.Tabulated data - Area vs. Pressure— The pressure regulation range is the difference between the last and first elements of the Pressure at port B (gauge) vector parameter.Tabulated data - Volumetric flow rate vs. pressure— The pressure regulation range is the difference between the first and last elements of the Reference pressure at port B (gauge) vector parameter.

Area vs. Pressure Parameterizations

When you set Opening parameterization to Linear - Area

vs. pressure, the block calculates the valve area as

where the normalized pressure,, is

When the valve is in a near-open or near-closed position in the linear parameterization, you can maintain numerical robustness in your simulation by adjusting the Smoothing factor parameter. If the Smoothing factor parameter is nonzero, the block smoothly saturates the control pressure between pset and pmax. For more information, see Numerical Smoothing.

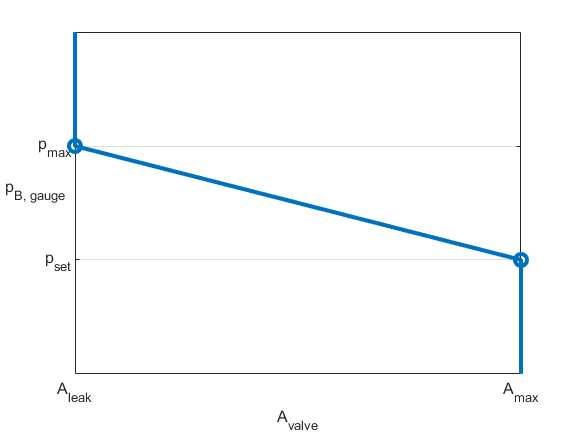

The figure demonstrates the opening characteristics of the valve when using the linear area parameterization. The opening area, Avalve, drops linearly with the outlet pressure, pB,gauge. The opening area ranges from Aleak to AMax, and the pressure operating range starts at pset and goes to pmax.

When you set Opening parameterization to Tabulated data -

Area vs. Pressure, the block calculates the opening area as

where:

pcontrol = pB,gauge is the control pressure.

pcontrol,TLU = pB,TLU + poffset.

pB,TLU is the Pressure at port B (gauge) vector parameter.

poffset is an internal pressure offset that causes the valve to start closing when pB,Gauge = pset, where poffset = pset - pB,TLU(1).

ATLU is the Opening area vector parameter.

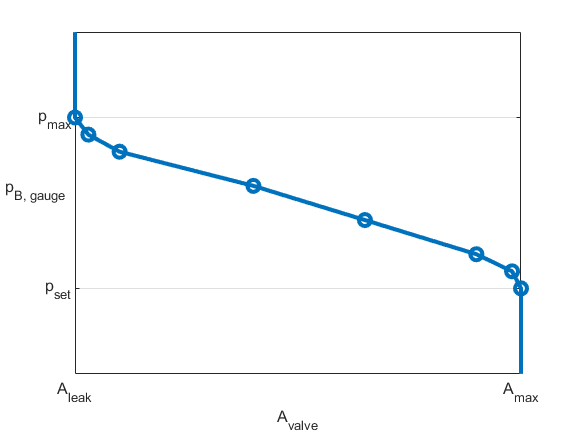

Amax and Aleak are the first and last parameters of the Opening area vector parameter, respectively. The figure demonstrates the opening characteristics of the valve when using the tabulated area parameterization.

When you set Opening parameterization to

Linear - Area vs. pressure or

Tabulated data - Area vs. Pressure, the block

conserves mass such that:

The block calculates the mass flow rate as

where:

Cd is the Discharge coefficient parameter.

Avalve is the instantaneous valve open area.

Aport is the Cross-sectional area at ports A and B parameter.

is the average fluid density.

Δp is the valve pressure difference pA – pB.

The critical pressure difference, Δpcrit, is the pressure differential associated with the Critical Reynolds number parameter, Recrit, the flow regime transition point between laminar and turbulent flow:

Pressure loss describes the reduction of pressure in the valve due to a decrease in area. The block calculates PRloss as:

Pressure recovery describes the positive pressure change in the valve due to an increase in area. If you do not want to capture this increase in pressure, clear the Pressure recovery check box. In this case, PRloss is 1.

The block determines the opening area, Avalve, using the valve opening dynamics.

For either area parameterization, you can choose to simulate the opening dynamics of the valve response. If you select Opening dynamics, the block adds a lag to the flow response when the valve opens, and Avalve becomes the dynamic opening area, Adyn. Otherwise, Avalve is the steady-state opening area. The block calculates the instantaneous change in the dynamic opening area based on the Opening time constant parameter, τ:

By default, the block ignores opening dynamics.

The block calculates the steady-state dynamics based on the control pressure, pcontrol, and using the same parameterization as the valve opening.

Volumetric Flow Rate vs. Pressure Parameterization

The volumetric flow rate parameterization equations refer to these quantities:

⩒TLU,ref is the Reference volumetric flow rate vector parameter.

PA,gauge,ref and PB,gauge,ref are the Reference pressure at port A (gauge) vector and Reference pressure at port B (gauge) vector parameters, respectively.

pset,gauge is either the Set pressure (gauge) parameter or the signal at port Ps.

K is the flow coefficient through the reducing stage, which the block calculates during the simulation.

is the average fluid density in the reducing valve.

Δp is the pressure drop across the valve for fluid flow.

Δpcrit is the critical pressure drop for fluid flow.

Cd is the discharge coefficient, which the block sets internally for the volumetric flow rate parameterization.

Recrit is the critical Reynolds number, which the block sets internally.

ν is the kinematic viscosity, which is constant for the isothermal liquid network.

When you set Opening parameterization to

Tabulated data - Volumetric flow rate vs. pressure,

the block calculates the smoothed mass flow rate of the reducing valve such that

where the block computes K using a

tablelookup function such that

The block calculates the control pressure as

where the block sets the drain pressure, pdrain, to 1 atm. The block calculates the reference control pressure vector as

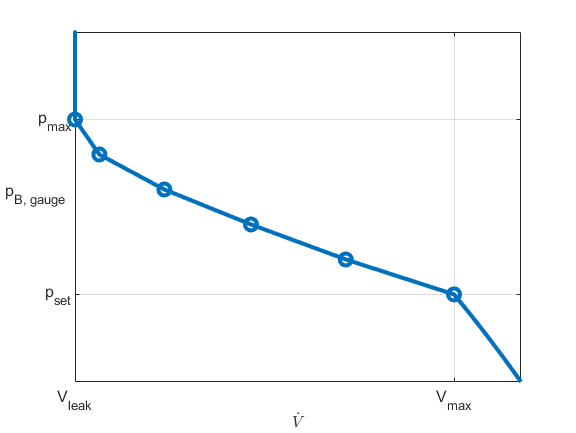

where poffset is an internally computed pressure offset that causes the valve to start shutting when pB,gauge,ref = pset,gauge. Thus, poffset = pset,gauge - pB,gauge,ref. The figure shows how the block controls pressure using the tabulated volumetric flow rate parameterization.

Faults

To model a fault, in the Faults section, click the Add fault hyperlink next to the fault that you want to model. Use the fault parameters to specify the fault properties. For more information about fault modeling, see Introduction to Simscape Faults.

Three fault options are available for the reducing valve and check valve. For the Reducing valve opening when faulted and Check valve opening when faulted parameters, you can choose:

Closed— The valve shuts to its smallest opening value, depending on the Opening parameterization parameter. When you set Opening parameterization to:Linear - Area vs. pressure— The valve area reduces to the value of the Leakage area parameter.Tabulated data - Area vs. pressure— The valve area reduces to the value of the last element in the Opening area vector parameter.Tabulated data - Volumetric flow rate vs. pressure— The flow coefficient reduces to the value of the last element of the derived flow coefficient lookup table, KTLU,Ref.

Open— The valve opens to its largest opening value, depending on the Opening parameterization parameter. When you set Opening parameterization to:Linear - Area vs. pressure— The valve area opens to the value of the Maximum opening area.Tabulated data - Area vs. pressure— The valve area opens to the value of the first element in the Opening area vector.Tabulated data - Volumetric flow rate vs. pressure— The flow coefficient reduces to the value of the first element of the derived flow coefficient lookup table, KTLU,Ref.

Maintain last value— The valve area remains at the valve opening area when the trigger occurred.

For the linear parameterization, numerical smoothing at the extremes of the valve area causes the minimum area applied to be larger than the Leakage area parameter, and the maximum is smaller than the Maximum orifice area parameter.

After the fault triggers, the valve remains at the faulted area for the rest of the simulation.

Predefined Parameterization

You can populate the block with pre-parameterized manufacturing data, which allows you to model a specific supplier component.

To load a predefined parameterization:

In the block dialog box, next to Selected part, click the "<click to select>" hyperlink next to Selected part in the block dialog box settings.

The Block Parameterization Manager window opens. Select a part from the menu and click Apply all. You can narrow the choices using the Manufacturer drop down menu.

You can close the Block Parameterization Manager menu. The block now has the parameterization that you specified.

You can compare current parameter settings with a specific supplier component in the Block Parameterization Manager window by selecting a part and viewing the data in the Compare selected part with block section.

Note

Predefined block parameterizations use available data sources to supply parameter values. The block substitutes engineering judgment and simplifying assumptions for missing data. As a result, expect some deviation between simulated and actual physical behavior. To ensure accuracy, validate the simulated behavior against experimental data and refine your component models as necessary.

To learn more, see List of Pre-Parameterized Components.