Communicate with Hardware Using Connected IO

You can use Connected IO to communicate with the IO peripherals on the hardware during simulation.

Simulation with Connected IO is an intermediate step in the Model-Based Design workflow that bridges the gap between simulation and code generation by enabling Simulink® to communicate with the hardware before deploying the model on the hardware. Connected IO enables you to modify your model design and monitor the effect of the modified design using the peripheral data from the hardware in a near real-time environment. You are not required to deploy the model on the hardware to monitor the effect of the modified design, which accelerates the simulation process.

These sections explain:

How to Enable Connected IO

To simulate a model in Connected IO, perform the following steps:

Open a Simulink model.

Press CTRL+E to open the Configuration Parameters dialog box.

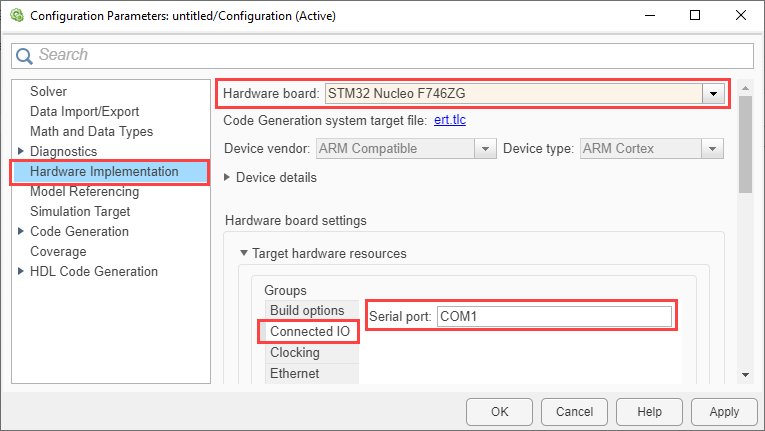

In the Configuration Parameters dialog box, select Hardware Implementation.

Set the Hardware board parameter to any Nucleo board listed in the Supported Nucleo Boards and Blocks with Connected IO section. For example,

STM32 Nucleo F746ZG. This selection automatically populates the parameters in the Hardware board settings with the default values for the Nucleo hardware.From the Groups list under Target hardware resources, select Connected IO.

Specify the port to which the board is connected, for example

COM1.

Click Apply. Click OK to close the dialog box.

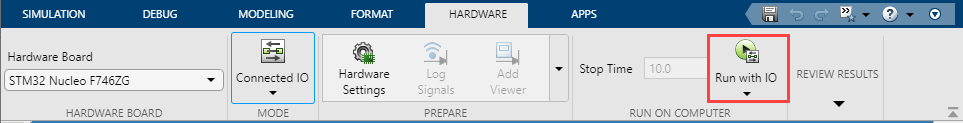

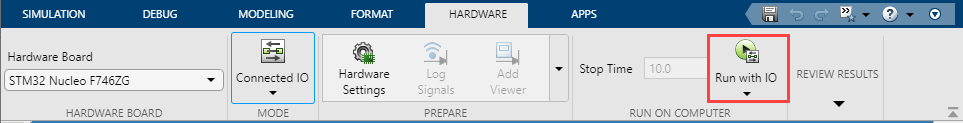

Go to Hardware tab, click on

Run on Boardand select Connected IO (inputs/outputs mode).

Optionally, you can change the rate of simulation by clicking Run with IO. For more information, see Simulation Pacing Options.

Note

The server for connected IO is built using

GNU Tools for ARM Embedded Processorstoolchain irrespective of the toolchain configured in Model Configuration Parameters.

Supported Nucleo Boards and Blocks with Connected IO

The Connected IO described here applies to the Simulink Coder™ Support Package for STMicroelectronics® Nucleo Boards on these STMicroelectronics Nucleo boards and blocks:

Source blocks: Without Connected IO, these source blocks output zero during simulation. With Connected IO, these blocks read data from the peripherals of the hardware during simulation.

Sink blocks: Without Connected IO, these sink blocks do not have any role during simulation. With Connected IO, these blocks write data to the peripherals of the hardware during simulation.

STMicroelectronics Nucleo Boards Source Blocks Sink Blocks Nucleo - F401RE

Nucleo - F103RB

Nucleo - L476RG

Nucleo - L053R8

Nucleo - F746ZG

Nucleo - F411RE

Nucleo - F767ZI

Nucleo - F302R8

How Connected IO Works

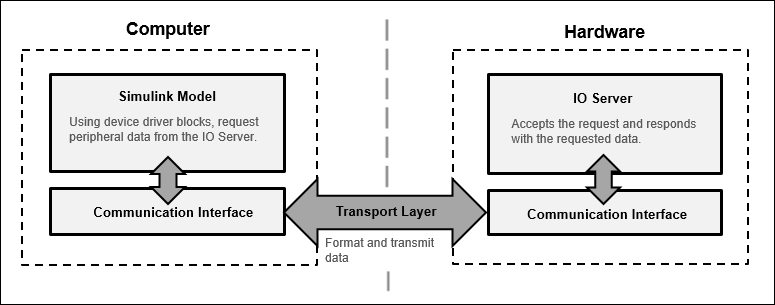

Connected IO creates a communication interface that enables the Simulink model and the IO Server to communicate with each other. The Simulink model resides in your computer, and the IO Server is an engine on the hardware that contains all peripheral functions. The transport layer formats and transmits the data using the communication interface.

This diagram shows the connection that the Connected IO creates between your computer and the hardware.

Communication with Connected IO

When you simulate a Simulink model in with Connected IO:

The device driver blocks (for example, Digital Read and Digital Write blocks) in the model request peripheral data from the IO Server.

The IO Server accepts the request and responds with the requested data. You can use any Simulink sink or dashboard block to view the received data. Using the peripheral data received, you can verify that your model design meets the requirements.

If necessary, you can modify the design by adding, removing, or replacing any block in the Simulink model.

After the model is modified, resimulate the model. During simulation, the data request from the model is communicated to the hardware. You can continue to modify and simulate the model until the expected behavior is achieved.

Note

The communication in Connected IO is an on-demand process. The hardware sends data only when receiving a data request from the Simulink model.

You do not have to build, deploy, and run the model on the hardware to monitor the effects of your changes in your model design.

How Connected IO Differs from External Mode

Connected IO and External mode both enable you to communicate with the hardware during simulation. However, you use Connected IO and External mode for different purposes. The table shows the actions that you can perform with each mode.

| Action | External Mode | Connected IO |

|---|---|---|

| Obtain real-time data | You can obtain real-time data with External mode. | Enable simulation pacing to get near real-time data. For more information, see Simulation Pacing Options. |

| Timing analysis of real-time data | Timing analysis of real-time data is possible because the Simulink model is running on the hardware in real-time. | Timing analysis of real-time data is not possible because the Simulink model is running in your computer and not on the hardware. |

| Code generation | Code is generated on the hardware. | No code is generated. |

Connected IO in Model-Based Design

Simulink communicates with the hardware only when the code is generated and the model is deployed on the hardware in External mode. Simulation with Connected IO is an intermediate step in the model-based design workflow that bridges the gap between simulation and code generation by enabling Simulink to communicate with the hardware before deploying the model on the hardware.

This Model-Based Design Workflow diagram displays a model-based workflow:

Create a Simulink model.

Simulate the model in:

Normal mode simulation without Connected IO: There is no hardware interaction and no code generation.

Simulation with Connected IO: The model communicates with the hardware. There is no code generation.

External mode: The model is deployed on the hardware and generates code.

Deploy the model to the hardware.

Model-Based Design Workflow