Results for

Hello Everyone,

I want to model an electric vehicle in simscape electrical, I have few quiries regarding it.

- I have modelled an 3-Phase inverter, and used ee_getPowerLossSumary to get switching losses, and the results are okay as i was expecting, but now is there any other function to calculate conduction losses?

- I want to connect a BLDC motor, I have few parameters from manufacturers datasheet, but not all the parameters, so what would the best way according to your understanding, to model motor losses (Copper + Core).

I'm trying to calculate major fundamental losses of an EV. Looking for your inputs on this.

Thank you!

i am trying to build a pulse radar using barker codes. i modulate the barker code and sine wave and added some noise as well. then i attached a matched filter whose parameters are shown in the image. and then made an attempt to demodulate, which i don't think is right. can someone please help me with the matched filter- like are the coefficients right? and also what else can i add remove and demodulate/detect.

PLEASE HELP ME OUT HERE I HAVE BEEN STUCK FOR QUITE A WHILE AND UNABLE TO FIGURE OUT HOW TO GO FURTHER

I need your help.

I am working on a simulink model and I want whenever run it, I give it some inputs. e.g. I can give it different heights when I want it to work.

I defined a file.m in the same directory and same name. but whenever I run it I face this error:

What should I do?

Has anyone ever been in this situation. When I use the ODE toolbox to find some complex system of equations with coefficients that vary greatly in order of magnitude, the results are completely incorrect. If you are in the same situation or know a solution, welcome to discuss with me, thank you!

Hi Any one knows how to interface delta VFD MS300 with matlab to control motor speed and

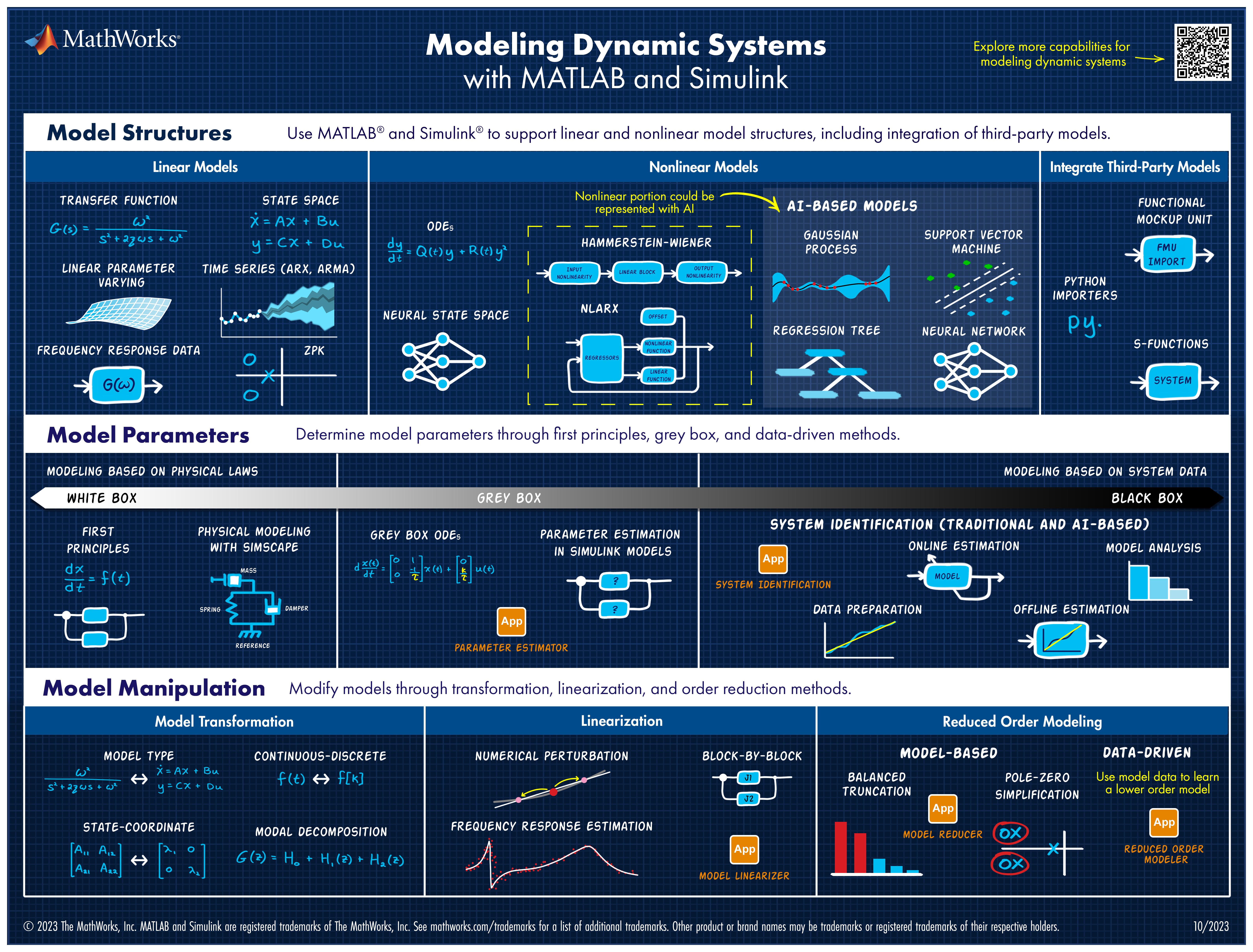

Explore all the capabilities for Modeling Dynamic Systems while keeping them handy with this Cheat Sheet - Download Now.

Hi,

I'm trying to install R2023b silently on Windows 10 Enterprise 22H2. The process starts but fails 10% into everything.

End of the file C:\tempmatlab\R2023b\installer_input.txt

(Dec 20, 2023 08:43:48) Session key: 5955da33-7f96-454a-b24a-aa1914758a09

(Dec 20, 2023 08:43:49) Product Files Folder: C:\tempmatlab\R2023b\archives

(Dec 20, 2023 08:43:52) License Agreement validation is successful.

(Dec 20, 2023 08:43:52) FIK validation is successful.

(Dec 20, 2023 08:43:52) License File validation is successful.

(Dec 20, 2023 08:43:52) Folder validation is successful.

(Dec 20, 2023 08:43:52) Product selection validation is successful.

(Dec 20, 2023 08:43:52) Confirm Selections

(Dec 20, 2023 08:43:52) Destination

(Dec 20, 2023 08:43:52) C:\Program Files\MATLAB\R2023b

(Dec 20, 2023 08:43:52) Products

(Dec 20, 2023 08:43:52) 113 of 113 products

(Dec 20, 2023 08:43:52) 23.74 GB required

(Dec 20, 2023 08:44:47) 1%

(Dec 20, 2023 08:45:09) 2%

(Dec 20, 2023 08:46:25) 3%

(Dec 20, 2023 08:46:40) 4%

(Dec 20, 2023 08:47:12) 5%

(Dec 20, 2023 08:47:20) 10%

(Dec 20, 2023 08:47:48) Exiting with status -2

(Dec 20, 2023 08:47:48) End - Unsuccessful

Both a FIK & license.dat are accessible during the install. There is 80GB of free disk space as well. No one is logged in to Windows when the install is performed. What does status -2 mean?

Thnaks!

I have encountered a problem. I want to study the direction of PHEVP2 configuration energy control strategy, but the whole vehicle model has stumped me. I don't know how to proceed, and every time I run, an error message will be reported. I don't understand where the problem lies?

Никак не получается создать новый ThinkHTTP так как пишет что URL?АДРЕСС СТРАНИЦЕ НЕ ДЕЙСТВИТЕЛЬНЫЙ

Here's the English translation. "I can't create a new ThinkHTTP because it says that the URL is not valid"

I'm going to customize the example of the MATLAB px4 hitl simulation and apply it to our current plane called SkysurferX8. I've calculated the aerodynamic factor and put it all in, but there's a problem. I wonder which code part of the example should be modified for trim flight speed, posture angle, etc. If you know any experts, I'd like to ask for your advice.

Example:

A=[-1.0000 0.1667 -2.9897

0.3624 -1.0604 -0.5243

4.0990 -4.5547 7.0303]

[L,U]=lu(A)

L=[-0.2440 1.0000 0

0.0884 0.6964 1.0000

1.0000 0 0]

U=[4.0990 -4.5547 7.0303

0 -0.9445 -1.2746

0 0 -0.2583]

A correct answer is

L=[1.0000 0 0

-0.3624 1.0000 0

-4.0990 3.8714 1.0000]

U=[-1.0000 0.1667 -2.9897

0 -1.0000 -1.6078

0 0 1.0000]

Hello, I am designing an MPC controller for a 4th order plant, which has a 1x1 input and two outputs. In the first instance, this controller is using the quadprog solver for the optimization method. I would like to know if this is what I am doing. designing in the first instance is correct or is there some strange detail, I insert the code that I used for the script and a test of the simulink block used:

%%%%%%%%%% Sistema de control predictivo MPC QUAD PROG %%%%%%%%%%%%%%%

clc

clear all

close all

%La planta RFL se puede modelar como un sistema con respuesta oscilatoria

%de segundo orden debido a las vibraciones de la barra modelandose de la

%siguiente manera: J*x''+Bx'+Kx=0, con solución en laplace de la forma:

%X(s)= Xo/J*(s^2+(B/J)*s+K/J)^-1 y se iguala a la respuesta del sistema

%s^2=2*chi*w_n*s+w_n^2 y se tiene que w_n^2=K/J, 2*chi*w_n=B/J

%Especificaciones de la planta

%tiempo de seteo del servo ts<=0.5 [s], llega a estado estacionario

%porcentaje de overshoot inferior a 7.5%

%máximo angulo de deflexión de la barra |alfa |< 10 deg

%máximo voltaje de control |Vm| <=10 [V]

%% Parámetros de la planta RFL%

Beq=0.004; %Coeficiente de viscosidad de fricción equivalente en [N*m]/(rad/s)

Jeq=2.08e-3; %Momento de inercia equivalente en kg*m^2

ml=0.065; %Masa de la barra en kg

Ll=0.419; %Largo de la barra en m

w_n=19.4495; %Frecuencia de oscilacion en [rad/s]

Jl=(ml*Ll^2)/3; %Momento de inercia de la barra en kg*m^2 de la forma (ml*Ll^2)/3

Ks=Jl*w_n^2; %Fricción o dureza de la barra en N*m/rad

%% Parametros del filtro

% SRV02 filtro pasa altos en control PD utilizado para computar la

% velocidad theta y alfa

% Frecuencias de corte en (rad/s)

wcf_1 = 2*pi*50;

wcf_2 = 2*pi*10;

%% Matrices de la planta a representar en V.E.

A=[0 0 1 0; 0 0 0 1; 0 Ks/Jeq -Beq/Jeq 0; 0 -Ks*(Jl+Jeq)/(Jl*Jeq) Beq/Jeq 0];

B=[0;0;1/Jeq;-1/Jeq];

C=[1 0 0 0;0 1 0 0];

D=[0;0];

%% Se representa en variables de estado la planta RFL

sys_RFL=ss(A,B,C,D);

x_0 = [45;0;0;0]; %Condiciones iniciales, si hay efectos en alfa no hay solucion, es decir estado 2 y estado 4

%% Varables de estado en tiempo discreto

T_sample=2.02; %Tiempo de muestro en discreto

tz_RFL=c2d(sys_RFL,T_sample); %Conversión a tiempo discreto de la matriz

[Ad,Bd,Cd,Dd]=ssdata(tz_RFL); %Matrices en tiempo discreto

n=length(Ad); %Largo de la matriz A discreta

[L_1,P_1,pol_1] = dlqr(Ad,Bd,eye(4),eye(1));

%Ax=Ad-Bd*L_1;

%% Constantes y Restricciones

N=5; %Horizonte de prediccion

x_min= [-90;-8;-0;-0]; %Restricciones de estado mínimas

x_max= [90;8;0;0]; %Restricciones de estado máximas

u_min= -10; %Restricciones de entrada mínimas

u_max= 10; %Restricciones de entrada mínimas

x_Nmin= x_min; %Restricciones de estado mínimas

x_Nmax= x_max; %Restricciones de estado máximas

Ipos= eye(N); %a los estados

Ineg= -eye(N); %a los estados

Q=C'*C; %Matriz de peso de estado Q=C'*C

R=eye(size(B,2)); %Matriz de peso actuación 1 |Posiblemente haya que ajustar los valores

[L_inf, PN, ~] = dlqr(Ad,Bd,Q,R);

and the test code:

options = optimset('Display','off');

%%%Condiciones iniciales

x0=x_0;

%%%Determinando las dimenciones del sistema

n = length(A); % largo de A

dimA = size(A,1);

dimB = size(B,2);

uvec = zeros(dimB*N,1);

coder.extrinsic('quadprog') % Utiliza quadprog

%% Calculo de la matriz Oa y Aa

%%%Inicializando las matrices Oa y Aa que definen el costo de MPC

Oa = zeros(dimA*N,dimB*N);

Aa = zeros(dimA*N,dimA);

for k = 1:N

Oa(n*k-(n-1):n*k,1) = (A^(k-1))*B; %Se define la primera columna de la matriz Oa

end

for j = 2:N

for k = j:N

Oa(n*k-(n-1):n*k,j) = Oa(n*(k-1)-(n-1):n*(k-1),j-1); %Desde la segunda columna de la matriz Oa

end

end

for k = 1:N

Aa(n*k-(n-1):n*k,:) = A^k ; %Se define la matriz Aa

end

Aa_N = A^N;

Oa_N = Oa(end-3:end,:); %Últimos 4 estados de Oa

%% Matrices y Restricciones

%%%Calculo de H y F para el costo de MPC

H = 2*(kron(eye(N),R)+Oa'*blkdiag(kron(eye(N-1),Q),P_1)*Oa);

H = (H+H')/2;

h = ((2*x0'*Aa'*blkdiag(kron(eye(N-1),Q),P_1)*Oa)');

%%%Restricciones ¿de la señal de estado

%%%Matriz M

Oa_Nineq = [Oa_N;-Oa_N];

Aineq = [Oa;-Oa];

%%%Matriz c

ba1_N = x_Nmax-Aa_N*x0;

ba2_N = -x_Nmin+Aa_N*x0;

Ba_Nineq = [ba1_N;ba2_N];

Bineq = [repmat(x_max,N,1)-Aa*x0;repmat(-x_min,N,1)+Aa*x0];

%%% Restricciones de la señal de entrada

LB = u_min*ones(N,1);

UB = u_max*ones(N,1);

%% Restricciones agrupadas

G = [Oa_Nineq;Aineq;Ipos;Ineg];

g = [Ba_Nineq;Bineq;UB;-LB];

%%%Vector de salida

uvec = quadprog(H,h,G,g,[],[],[],[],[],options); % resuelve con quadprog

u = uvec(1);

I do this for a plant without reference, as long as it goes to state zero with the calculated input

I want to set wind speed 2m/s for 5second, then next 5 second 4m/s, then next 5 second 6m/s.......

For doing this which block should I use in simulink?

American style football

12%

Soccer / football

39%

baseball

5%

basketball

12%

tennis or golf

7%

rugby, track, cricket, racing, etc.

26%

3712 votes

You reached this milestone by providing valuable contribution to the community since you started answering questions in Since September 2018.

You provided 3984 answers and received 1142 votes. You are ranked #24 in the community. Thank you for your contribution to the community and please keep up the good track record!

MATLAB Central Team

So, I'm trying to find the rate of climb against the velocity.

Both of these variables are 1 x 100 vectors.

rate of climb = v.*(T-D)./w

where w is a constant. t,d and v are all arrays of 1 x 100 row vectors. I was wondering ways to find the derivative at the local maximum. Examples would be appreciated.

I'm using app designer to link it with one simulink model of mine. I had used editfield (numeric) in app such that inputs to simulink model can be given through this app. The variables declared in app code will be used in simulink model. But when I give numeric inputs to app and run, the variables in simulink are showing it as 0 in the base workspace too.

Syntax used for assigning a variable to editfield is:

assignin("base", "variablename", app.EditFieldName.Value);

Please give me the solution to this.

This is my code

%send food and medicine in flood situation

% 1. create map

clc

clear

tic

map3D = occupancyMap3D; % create space for

[xGround,yGround,zGround] = meshgrid(0:240,0:350, 0); %set floor x=500 y=500

xyzGround = [xGround(:) yGround(:) zGround(:)]; %use for mergegrid

occval = 0;

setOccupancy(map3D,xyzGround,occval)

% xspace = 20 y = 45 create

[xB1, yB1, zB1] = meshgrid(50:130, 60:110, 0:20); %unionmall

[xB2, yB2, zB2] = meshgrid(80:250, 160:240, 0:30); %centralladprao

[xB3, yB3, zB3] = meshgrid(220:250, 290:340, 0:60); %centarahotel

[xB4, yB4, zB4] = meshgrid(0:30, 10:40, 0:80); %condo

[xB5, yB5, zB5] = meshgrid(150:170, 80:100, 0:10); %house1

[xB6, yB6, zB6] = meshgrid(180:200, 80:100, 0:10); %house2

[xB7, yB7, zB7] = meshgrid(210:230, 80:100, 0:10); %house3

[xB11, yB11, zB11] = meshgrid(240:270, 80:100, 0:10); %house7

[xB8, yB8, zB8] = meshgrid(150:170, 50:70, 0:10); %house4

[xB9, yB9, zB9] = meshgrid(180:200, 50:70, 0:10); %house5

[xB10, yB10, zB10] = meshgrid(210:230, 50:70, 0:10); %house6

[xB12, yB12, zB12] = meshgrid(240:270, 50:70, 0:10); %house8

[xB13, yB13, zB13] = meshgrid(200:260, 0:30, 0:13); %villageoffice

xyzB = [xB1(:), yB1(:), zB1(:);

xB2(:), yB2(:), zB2(:);

xB3(:), yB3(:), zB3(:);

xB4(:), yB4(:), zB4(:);

xB5(:), yB5(:), zB5(:);

xB6(:), yB6(:), zB6(:);

xB7(:), yB7(:), zB7(:);

xB8(:), yB8(:), zB8(:);

xB9(:), yB9(:), zB9(:);

xB10(:), yB10(:), zB10(:);

xB11(:), yB11(:), zB11(:);

xB12(:), yB12(:), zB12(:);

xB13(:), yB13(:), zB13(:);];

obs = 0.65; % ;=not show in command window

my3Dmap = map3D;

updateOccupancy(my3Dmap,xyzB,obs);

%show(my3Dmap);

% 2. distination

%my3Dmap.FreeThreshold = my3Dmap.OccupiedThreshold;

startPose = [50 60 25 pi/2;

250 310 65 pi/2;

100 170 35 pi/2;

100 30 85 pi/2;

155 90 15 pi/2;

250 60 15 pi/2;

160 60 15 pi/2

220 15 20 pi/2;];

goalPose = startPose;

ss = ExampleHelperUAVStateSpace("MaxRollAngle",pi/3,...

"AirSpeed",5,...

"FlightPathAngleLimit",[-0.5 0.5],...

"Bounds",[-10 400;-10 4000; -10 100; -pi pi]);

%threshold = [(goalPose-0.5)' (goalPose+0.5)'; -pi pi];

%setWorkspaceGoalRegion(ss,goalPose,threshold)

sv = validatorOccupancyMap3D(ss,"Map",my3Dmap);

sv.ValidationDistance = 0.5;

planner = plannerBiRRT(ss,sv);

planner.MaxConnectionDistance = 100;

%planner.GoalBias = 0.10;

%1,0.1,0.15,0.5,0.2,0.13,

planner.MaxIterations = 100000;

%planner.GoalReachedFcn = @(~,x,y)(norm(x(1:3)-y(1:3)) < 5);

planner.MaxNumTreeNodes = 10000;

numPose = length(startPose);

distances = zeros(numPose, numPose);

for i = 1:numPose

for j = 1:numPose

if i ~= j

rng(100, "twister");

start = [startPose(i,1), startPose(i,2), startPose(i,3), startPose(i,4)];

goal = [goalPose(j,1), goalPose(j,2), goalPose(j,3), goalPose(j,4)];

[pthObj, solnInfo] = plan(planner, start, goal);

smoothWaypointsObj = exampleHelperUAVPathSmoothing(ss, sv, pthObj);

distances(i, j) = pathLength(smoothWaypointsObj);

end

end

end

toc

and the error below

Hi, I have this equation for moment-axial force interaction: 0.25*(M/M0)^2 + (N/N0) = 1. This equation produces the following curve. Now, I need to make a change to this equation so that the first term becomes (M/M0)^2, and the second term can be changed while keeping (N/N0). The other side of the equation remains the same. ((M/M0)^2+?? = 1). I need to get the same curve as in the figure.

Hi, I have this equation for moment-axial force interaction: 0.25*(M/M0)^2 + (N/N0) = 1. This equation produces the following curve. Now, I need to make a change to this equation so that the first term becomes (M/M0)^2, and the second term can be changed while keeping (N/N0). The other side of the equation remains the same. ((M/M0)^2+?? = 1). I need to get the same curve as in the figure.Hello everyone,

I am trying simulate a gas turbine system for my course on modelling and optimization of energy system. I have come out with a design consisting of a compressor, air preheater, combustion chamber and gas turbine. When I try to do the modelling in Simulink, I couldnt find something similar to combustion chamber. Does anyone have any experience in doing this?

Orginal Design:

I have also amended it and come out with second design, where I change to combustion chamber to a heater and the exhaust air is recycled back to air compressor, making it a closed loop system. But I am also unable to find heater from the simulink library, the closest i can get is convective heat transfer. Can someone help on this too and if the closed loop system is feasible to model?

Design 2 :