Optimize Your Functional Safety Toolchain with MATLAB, Simulink and Polyspace

Overview

Choosing a toolchain for developing functionally safe electrical and/or electronic (E/E) systems is a demanding task. On one hand, the toolchain has to let engineers automate as many repetitive (and as such error-prone) tasks as possible.

Automation capabilities on the other hand may lead to silently injecting faults into the final product, or failing to detect issues therein. Therefore, standards require to manage the risk associated with automation use cases of development toolchains.

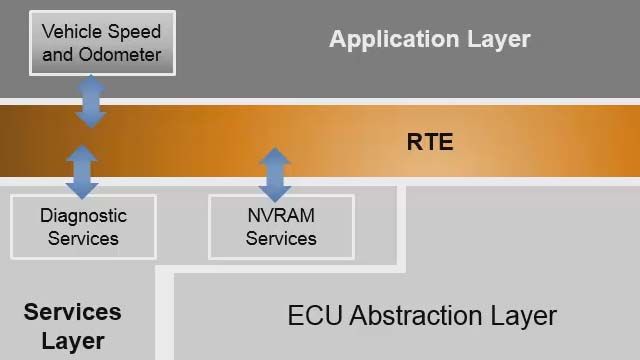

In this webinar, you will learn how to end-2-end develop high integrity systems using MATLAB, Simulink and Polyspace family of products. Hereby, you will learn how developing application software is ideally performed with Model-Based Design and production code generation, and how manual coding can support the development of non-application software components. You will also learn what Model-Based Design offers for effective and efficient integration and integration testing of application and non-application software.

Highlights

- Introduction to Functional safety and the importance of tool integration

- Reasons and strategies to optimize toolchains for functional safety

- Using Model-Based Design for system and software architectures

- Using MATLAB, Simulink and Polyspace for Unit detailed design and unit verification

- Integration testing with Model-Based Design

About the Presenters

Mohammad Abu-Alqumsan is a Product Manager at MathWorks. Mohammad focuses on quality, safety and cybersecurity and consults with industry participants on qualifying tools and developing workflows that comply with popular certification standards such as ISO 26262, SOTIF, IEC 61508, ISO 21434 and Automotive SPICE.

Alex Shin is a Principal Application Engineer at MathWorks. He specialises in helping customers in the area of simulation, verification and automatic code generation, primarily for commercial/production projects. His recent work includes defining simulation and verification process and implementation of Model-Based Design tools in large organisations. Mr. Shin received Bachelor’s degree from University of New South Wales in mechatronics engineering.

Recorded: 27 Jun 2023