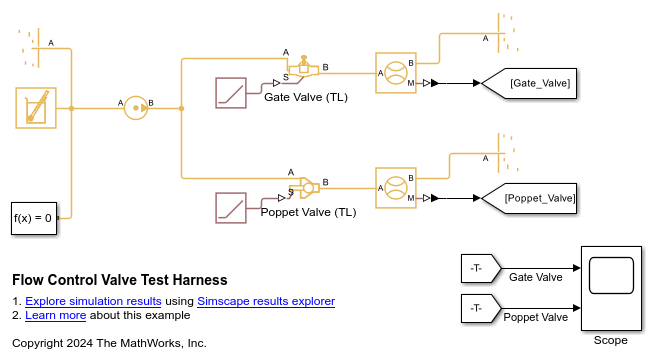

Poppet Valve (TL)

Poppet flow control valve in a thermal liquid network

Libraries:

Simscape /

Fluids /

Thermal Liquid /

Valves & Orifices /

Flow Control Valves

Description

The Poppet Valve (TL) block represents the flow control within a thermal liquid network. You can specify the seat geometry as either sharp-edged or conical. Set the poppet displacement with the physical signal at port S.

Mass Balance

The mass conservation equation in the valve is

where:

is the mass flow rate into the valve through port A.

is the mass flow rate into the valve through port B.

Momentum Balance

The pressure differential over the valve is:

where:

pA is the pressure at port A.

pB is the pressure at port B.

is the mass flow rate.

ρAvg is the average liquid density.

Cd is the value of the Discharge coefficient parameter.

is the critical mass flow rate:

where:

Recr is the value of the Critical Reynolds number parameter.

μAvg is the average fluid dynamic viscosity.

S is the value of the Cross-sectional area at port A and B parameter.

PRLoss is the pressure ratio:

Energy Balance

The energy conservation equation in the valve is

where:

ϕA is the energy flow rate into the valve through port A.

ϕB is the energy flow rate into the valve through port B.

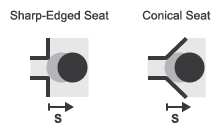

Opening Area With a Sharp-Edged Seat

When you set Valve seat specification to

Sharp-edged, the block calculates the valve opening

area using

where:

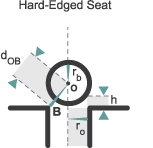

ro is the valve orifice radius.

rp is the valve poppet radius.

dOB(h) is the distance between the center of the poppet and the edge of the orifice. This distance is a function of the valve lift,h.

Aleak is the leakage area.

The maximum displacement, hmax, is

The figure shows a schematic of a hard-edged seat.

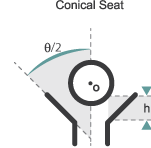

Opening Area With a Conical Seat

When you set Valve seat specification to

Conical, the block calculates the valve opening area

using a geometric relationship, such that

The maximum displacement, hmax, is:

where θ is the Cone angle. The figure shows a schematic of a conical seat.

Numerically Smoothed Displacement

The block calculates the poppet displacement, h, such that

where:

S is the physical signal input.

Smin is the Poppet position when in the seat parameter.

hMax is the maximum displacement.

If the Smoothing factor parameter is nonzero, the block smoothly

saturates the poppet displacement between 0 and

hMax.

For more information, see Numerical Smoothing.

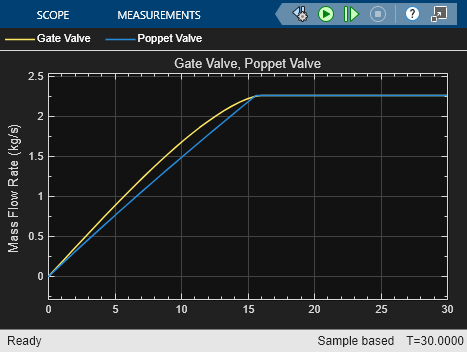

Examples

Ports

Conserving

Input

Parameters

Extended Capabilities

Version History

Introduced in R2016a